- March 3, 2023Students pursuing STEM education program talk with ATC, M.J. Electric and Electric TV Under an azure sky in the early…

- February 16, 2023At American Transmission Co., our job is to operate our transmission system safely and reliably, and we take that responsibility…

- February 13, 2023We care about the environment, particularly in areas where our facilities are in close proximity to known avian flyways. That’s…

- February 11, 2023ATC employees recently participated in the Woodland Elementary STEM Night in Kingsford, Mich. About 300 kindergarten through fourth grade students…

- January 4, 2023ATC has collectively awarded $65,000 to 18 recipients across its service area to plant trees and low-growing vegetation through its…

- December 3, 2022ATC is honored to complete the first season of our Spikes for STEM partnership with the University of Wisconsin Badgers,…

- November 19, 2022American Transmission Co., with the Milwaukee Bucks, have announced our seventh consecutive season of partnership for the Trees for Threes…

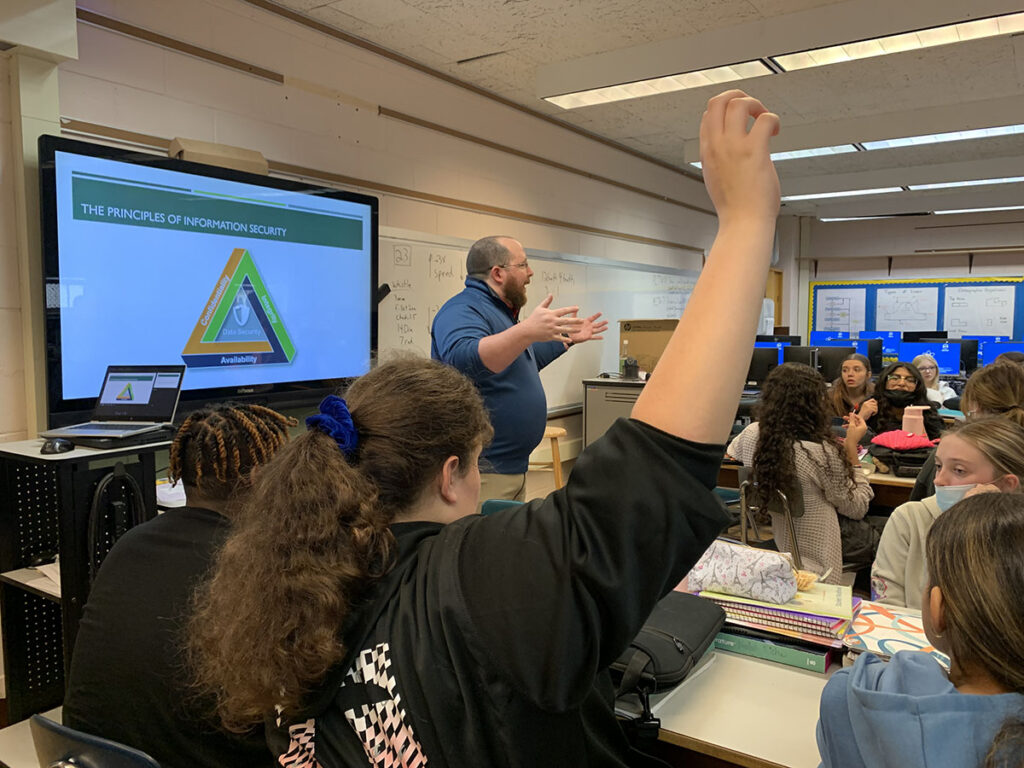

- October 13, 2022Science, technology, engineering and math skills are foundational to many critical job roles at American Transmission Co. We employ electrical…

- September 7, 2022Great Place to Work® and Fortune magazine have honored American Transmission Co. as one of the 2022 Best Workplaces in Manufacturing…

- August 10, 2022The town of Ledgeview, Wis., and the North Central Conservancy Trust are welcoming bees, birds, butterflies and other pollinators to…

- July 28, 2022On July 19, ATC interns participated in the United Way Intern Day of Action. The event featured interns from companies…

- July 20, 2022Aerial helicopter patrols are a valuable tool that American Transmission Co. deploys to periodically inspect our transmission lines. Riding shotgun…

- June 30, 2022Construction of the Darien and Paris Solar Network Upgrade Project is advancing in Kenosha County. The project will support the…